Forskning

Vår forskning utvecklar den industriella processen från behov till färdig produkt, samtidigt som ett mervärde skapas.

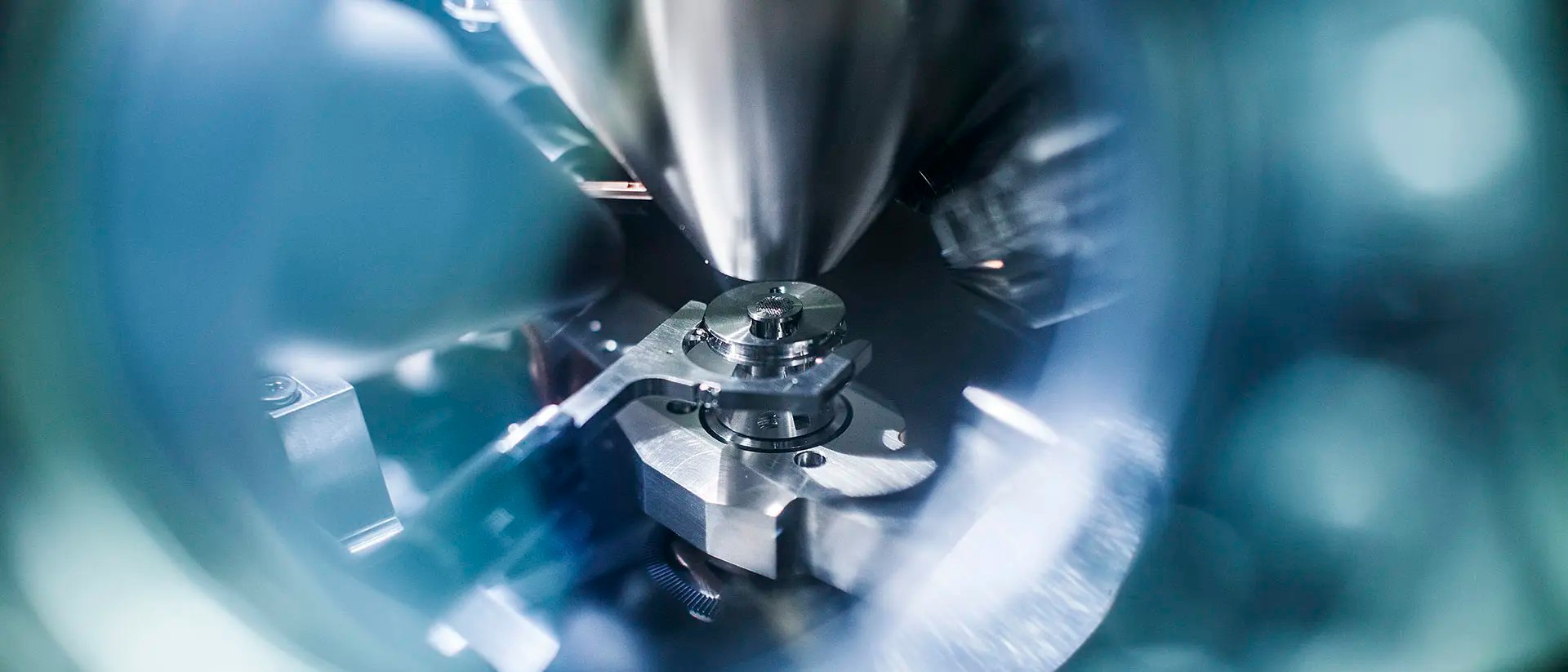

Nyttja våra laboratorier

Vår högkvalitativa laboratoriestruktur och maskinpark kan till viss del nyttjas av externa parter.

Utbildning

Vi utbildar morgondagens ingenjörer på grund- och avancerad nivå och bedriver forskarutbildning.