Materials technology – research based on the relationship between microstructure and mechanical properties of engineering metals.

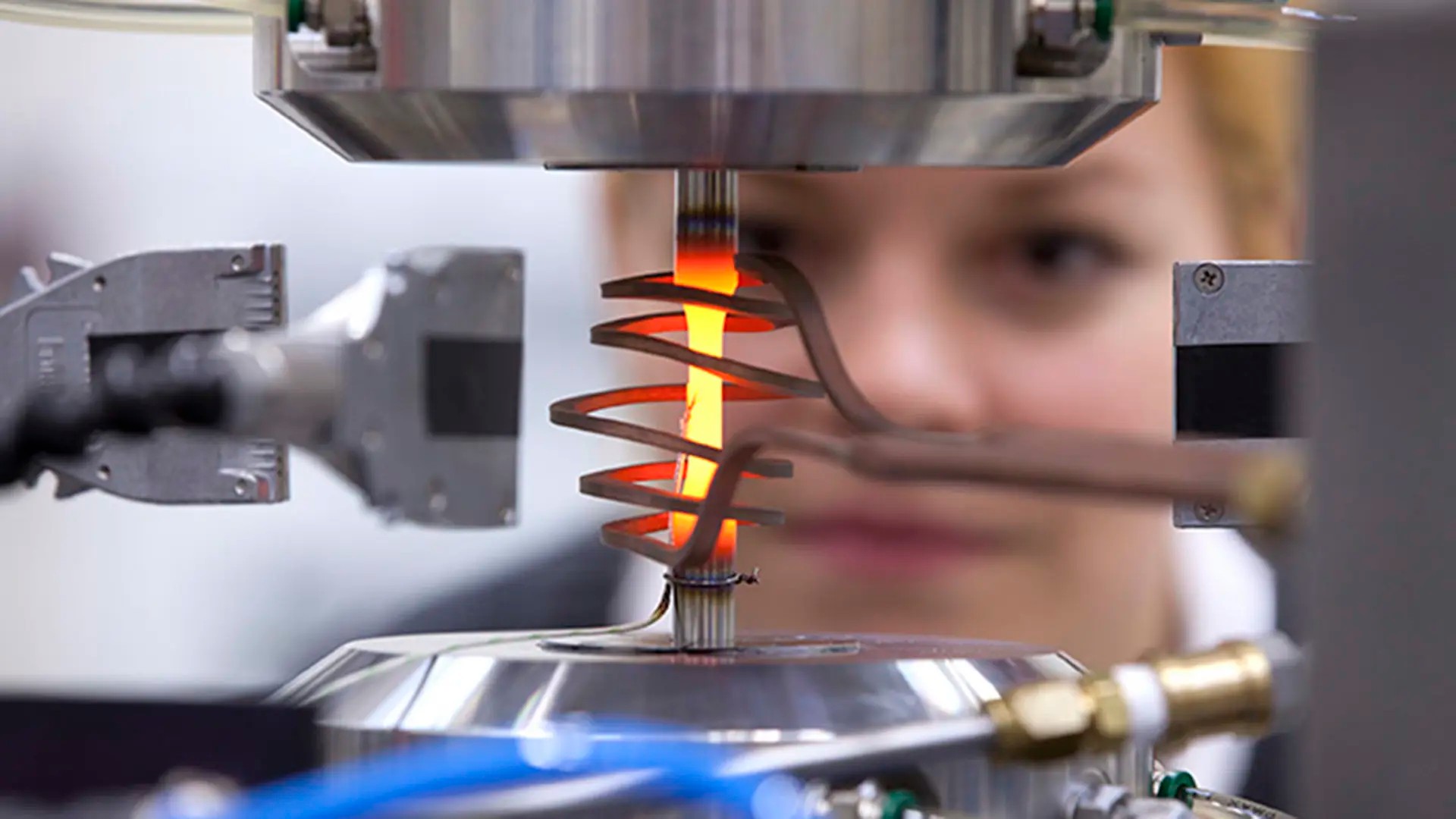

Studies focus on characterising fatigue behaviour by simulating realistic material states and loading conditions of components in service. Applications also include the deformation behaviour of metals in manufacturing processes such as heat treatment, additive manufacturing, forming and welding. Experiments are performed in fatigue test rigs with thermomechanical (TMF) and Axial-Torsion capabilities, and microstructures are characterised using microscopy, image analysis, X-ray diffraction and tomography. Mechanical properties are often implemented in material models for computational purposes. All research contributes to improving the performance and competitiveness of more sustainable technologies, aimed at reducing the consumption of primary metals and fossil fuels.

Overview of research activities

- Several research efforts on high pressure die casting of secondary aluminium alloys are initiating in different collaborations, such as the SCALE project which investigates alloy design to enable a more circular flow of metals in component manufacturing. The LIVSVERK project aims to increase the life of dies for high pressure die casting and our role is to evaluate the thermo-mechanical fatigue that occurs in dies due to thermal cycling.

- The reliable and sustainable operation of railways is another area of research. Understanding rolling contact fatigue (RCF) cracking in the deformed surface layer forming in railway wheels and rails requires the development of innovative testing techniques. Advanced microstructural characterisation, crack modelling and thermo-mechanical modelling will be carried out in collaboration. The projects are supported by several industrial partners within the Railway Mechanics Competence Centre CHARMEC and are linked to European research activities in the EU project EUROPE’S RAIL.

- High-performance gas turbine engines require advanced component manufacturing techniques. Complex geometries are subject to multi-axial stress states and thermal gradients in service. Advanced mechanical and microstructural characterisation is required for correct design and life prediction of such components. The BIFROST project will investigate the biaxial thermo-mechanical fatigue resistance of both forged and additively manufactured superalloys for use in civil aircraft engines.

The research group

- Full Professor, Engineering Materials, Industrial and Materials Science

- Professor, Engineering Materials, Industrial and Materials Science

- Doctoral Student, Engineering Materials, Industrial and Materials Science

- Doctoral Student, Materials and Manufacture, Industrial and Materials Science

- Doctoral Student, Engineering Materials, Industrial and Materials Science