For industries like automotive manufacturing, the potential of metal 3D printing is often limited by practical challenges. High costs and slow production speeds have made it difficult to scale up the technology for broader industrial use. Rasmus Gunnerek, PhD student at Chalmers University of Technology, address these limitations to help bring 3D printed steel into mainstream manufacturing.

“Compared to conventional manufacturing, metal 3D printing is relatively slow and expensive. My research focuses on how we can speed up the process without compromising too much on quality,” says Rasmus Gunnerek.

Understanding the trade-offs of faster printing

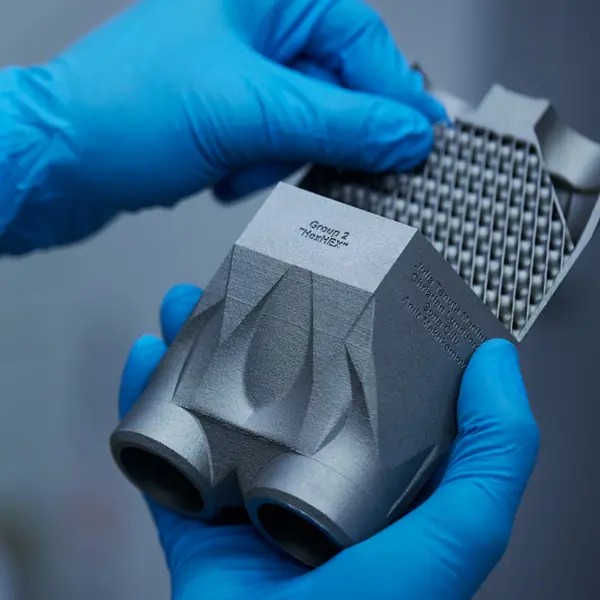

The research centers on ferrous alloys, steels commonly used in mass production industries. By adjusting key printing parameters such as laser scan speed, hatch distance, and layer thickness, Rasmus Gunnerek explores how to increase build speed while managing the resulting material defects.

“When we increase build speed, we often introduce internal defects like porosity. But not all defects are equally harmful. If we understand their characteristics, we can design components that tolerate them.”

His findings show that different parameter changes lead to different types of defects, which affect mechanical performance in distinct ways. For example, increasing hatch distance rather than scan speed resulted in more predictable fatigue performance.

Improving surface quality for complex components

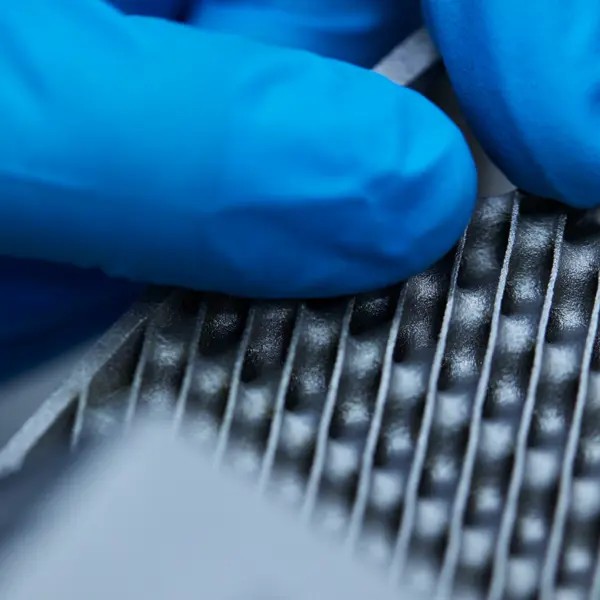

Another focus of the research is surface roughness, a known limitation of this form of metal 3D printing. Traditional machining methods often struggle with the complex geometries that 3D printing enables.

To address this, Rasmus Gunnerek evaluated two alternative surface treatments: electrochemical polishing, which uses fluid to remove material from internal surfaces, and chemical mechanical polishing, which uses vibration and non-abrasive media to smooth surfaces.

“Both surface treatments significantly improved fatigue performance, roughly doubling the fatigue life of the components. This shows their potential as effective complements in the use of metal 3D printing for ferrous alloys.”

The strength of 3D printing lies in its ability to create complex, lightweight components.

Potential for broader industrial use

While metal 3D printing is already used in sectors like the aviation and space industries, its adoption in more cost-sensitive fields such as automotive remains limited.

“The strength of 3D printing lies in its ability to create complex, lightweight components. In aerospace, even small weight savings are valuable. In the automotive industry, production speed and cost are much more critical.”

One promising application is on-demand manufacturing of spare parts. Instead of maintaining large inventories, companies could store digital files and print components as needed, saving both money and reducing environmental impact.

“If we can print faster and still meet performance requirements, we can reduce costs and make metal 3D printing more attractive for high-volume production.”

Collaboration with industry

Conducting his research within the Centre for Additive Manufacture – Metal (CAM2), Rasmus Gunnerek highlights the value of collaboration with other PhD students and close connections to industry.

“It’s been a unique setting. We’ve had constant input from companies, many of them facing similar challenges around productivity and process robustness. It’s been a valuable experience to have this close connection with the people you are trying to help.”

What comes next?

As he approaches his PhD defence, Rasmus Gunnerek reflects on the next steps of his research. He sees strong potential for applying his findings in industrial production environments, supporting the broader adoption of metal 3D printing.

“I’d like to implement different strategies for increased productivity in real application scenarios and see how they perform. It would also be interesting to continue developing the surface treatments. We’ve seen a lot of potential there, and I want to keep optimizing the techniques we’ve tested.”

Rasmus Gunnerek defends his PhD thesis on 13 May 2025

Read the thesis and see time and location of the defence.

- Doctor, Materials and Manufacture, Industrial and Materials Science