Since the start in 2017, Centre for Additive Manufacturing – Metal, CAM2, has driven significant innovation in additive manufacturing, contributing to Sweden’s continued competitive edge in this evolving field. Anna Wenemark, Global Technology Office Manager at Alfa Laval, and Chair of the Board at CAM2, shares her insights on the centre’s journey and key success factors.

Anna Wenemark, what were the key driving factors behind starting CAM2?

"In 2017, additive manufacturing was still a new area for us. While our knowledge was limited at the time, we recognized the need to deepen our understanding of the technology. Our goal was to bring together industry and academia to ensure Sweden’s continued competitiveness in the field. We have an ecosystem spanning from powder production to original equipment manufacturers (OEMs) and several machine suppliers in Sweden, giving us a strong position. By bringing together diverse partners we have strengthened our role in the sector. Collaboration is key to advancing new technologies, and we have succeeded in fostering it effectively."

What role has the collaboration between industry and academia played in CAM2’s development?

“The true value lies in our complementary strengths and driving forces. It is essential to understand the basic technology and its physical principles, and it is equally important to connect this knowledge to industrial applications. In phase one, our first five years of the centre, our industry partners were still learning about the technology. By phase two, we had a clear agenda on areas we wanted to further develop, and our collective maturity had significantly evolved."

"This could not have been achieved by any single company alone. This progress is the result of collaboration and a shared understanding that optimizing one part is not enough; we must consider the entire value chain. Today, more than 30 companies and five academic partners are actively collaborating on projects in the centre, sharing experiences, and learning from each other.”

This progress is the result of collaboration and a shared understanding that optimizing one part is not enough; we must consider the entire value chain.

What have been CAM2's most significant milestones so far?

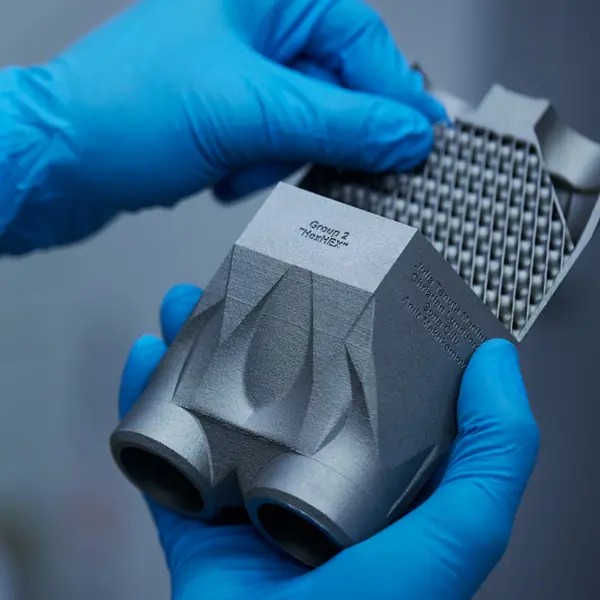

"One of our most significant achievements has been the maturation of the technology itself. While each partner has its own milestones, CAM2 has provided a pathway for the continued growth of additive manufacturing, enabling further efforts focused on its application, such as the RISE Application Center for Additive Manufacturing and our many spinoff projects."

"Collaboration across industry and academia, as well as between different industrial partners, has been essential for advancing the field. Sharing our experiences with this still emerging area has sparked curiosity and fostered a willingness to explore new initiatives. The active involvement of several SMEs has also been a crucial driver, further accelerating our development of additive manufacturing."

What do you think lies ahead for the field of additive manufacturing?

“As CAM2 enters its final years, it’s important to maximize the outcomes of our ongoing projects. We have built a robust network and accumulated extensive expertise. Our priority moving forward is to sustain these connections, continue our effective ways of working, and explore new paths for collaboration. The technology has matured significantly, but there’s still much to explore, and we’re likely to see major developments in the coming years."

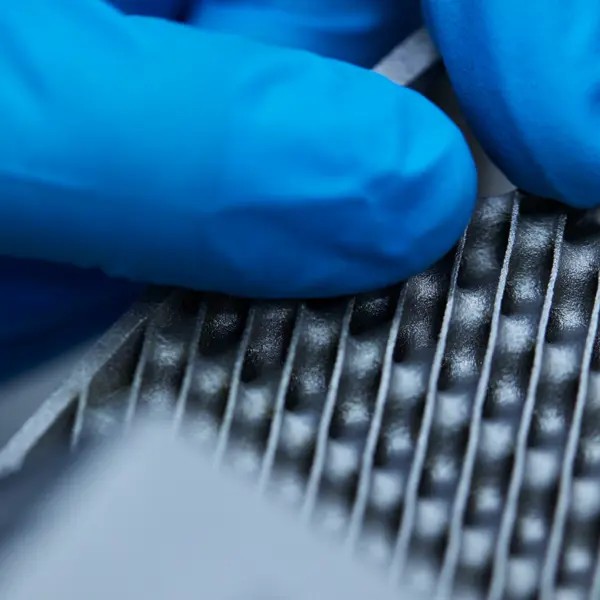

"CAM2 has played a vital role in raising the visibility of additive manufacturing by sharing results and showcasing potential applications, which is critical for industry-wide adoption. New materials, like copper and graphene, offer exciting possibilities, and the role of additive manufacturing will continue to grow through ongoing innovation and application.”

Centre for Additive Manufacture – Metal

Centre for Additive Manufacture – Metal, CAM2, is a Vinnova funded competence centre focusing on research and development of materials and processes for additive manufacturing (3D printing) of advanced metallic components. In the competence centers, universities, research institutes, companies and public actors are conducting applied research in close cooperation in areas that are important for Sweden's competitiveness.

Do you want to learn more?

Read more about Centre for Additive Manufacture – Metal