A new study could make gas turbines more reliable and efficient by addressing a challenge in manufacturing turbine blades. Researchers at the Centre for Additive Manufacture – Metal (CAM2) have developed an improved additive manufacturing (AM) method that reduces cracking and residual stress in metal components exposed to extreme heat and pressure.

Gas turbines operate under intense conditions, with components enduring extreme temperatures and mechanical loads. A major issue in manufacturing these parts is cracking, which weakens the metal and shortens its lifespan.

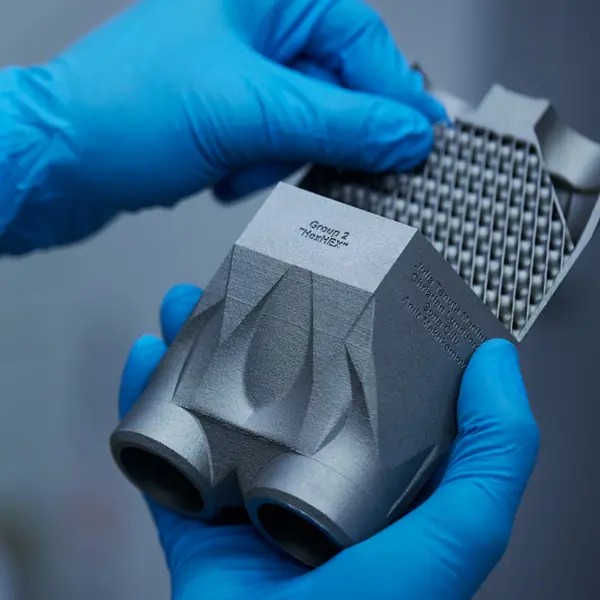

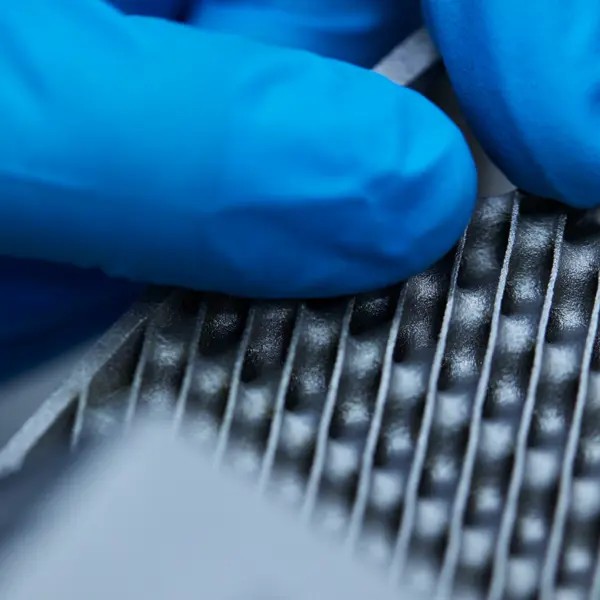

At CAM2, researchers have developed a way to reduce cracking when using additive manufacturing by adjusting how the metal is processed. Instead of using long, continuous laser scans, they tested shorter laser scan patterns that better control heat input. This adjustment helps distribute heat more evenly across the material, reducing the risk of cracks forming.

“The results indicate that such a scan strategy helps in minimizing both solidification cracking and residual stress, which improves the overall processibility of this alloy,” says Ahmed Fardan Jabir Hussain, Doctoral Student in Metal Additive Manufacturing at Chalmers University of Technology.

Potential for broader industrial applications

While the research focuses on a specific high-performance alloy, CM247LC, commonly used in gas turbines, the findings could also benefit other materials prone to similar cracking issues.

“Cracking occurs both in the production process and during heat treatments, which limits the use of these materials. This research brings us closer to making these materials more viable for such applications,” says Ahmed Fardan Jabir Hussain.

Enhancing durability by reducing internal stress

One of the most promising aspects of this research is its potential to reduce residual stress, a key factor in preventing strain age cracking (SAC). SAC is a common issue near stress concentrators, especially in final components like turbine blades. This improved process could lead to stronger, more durable components that better withstand high temperatures and stress.

“The scan strategy of short vectors can be applied locally near stress concentrators to create a microstructure resistant to strain age cracking. This microstructure tailoring is very attractive to industries that use such alloys for manufacturing,” says Ahmed Fardan Jabir Hussain.

Improving high-temperature performance

The research team is also working to ensure that the material can withstand extreme heat over long periods without deforming, a property known as creep performance. This is a crucial factor for turbine blades operating under high temperatures and loads.

“These alloys are designed for use in the hot sections of gas turbines, such as turbine blades. These blades endure very high loads and temperatures, so they must have strong high-temperature creep performance. We’re currently working on improving this to bring the creep performance closer to that of cast material,” says Ahmed Fardan Jabir Hussain.

More information about the research

Read the scientific article Microstructure tailoring for crack mitigation in CM247LC manufactured by powder bed fusion – Laser beam in Additive Manufacturing.

- Doctoral Student, Materials and Manufacture, Industrial and Materials Science