By fine-tuning the gases used in metal 3D printing, industrial PhD student Kai Zissel is bringing binder jetting closer to large-scale industrial use. Finalizing his PhD at Linde, within the CAM² research centre at Chalmers University of Technology, he is advancing a promising and still emerging 3D printing technology.

“My research has mainly been focused on the topic of processing atmospheres. How can we improve the binder jetting process by using tailored atmospheres or gas mixes?” says Kai Zissel.

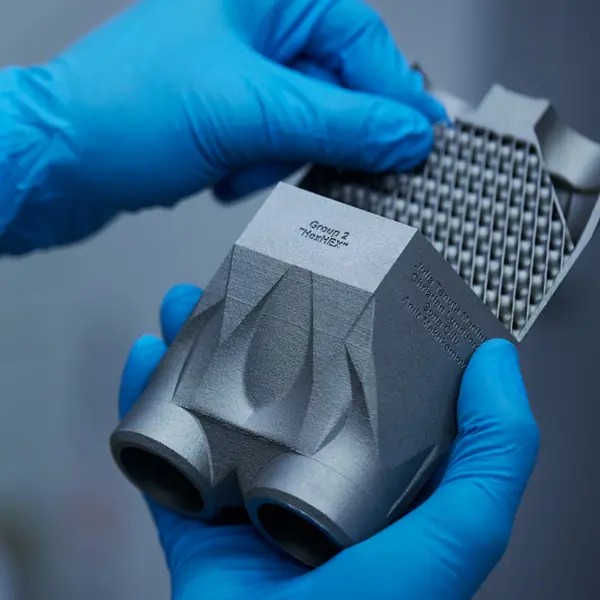

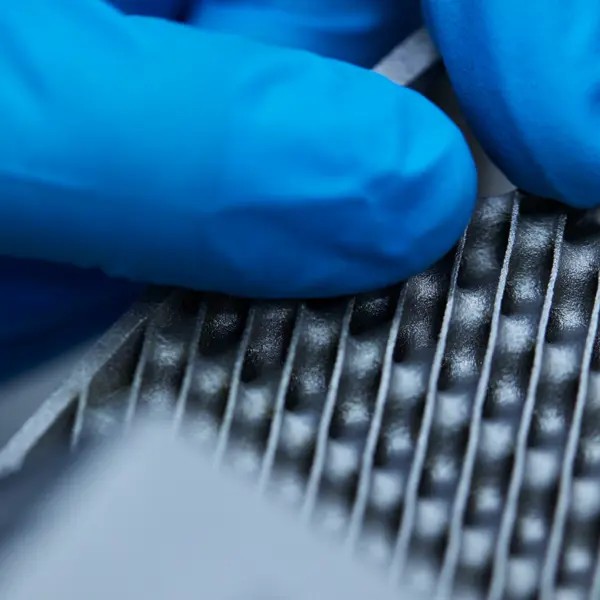

Binder jetting is a 3D printing technique that works a bit like an inkjet printer, except instead of ink and paper, it uses a liquid binder to glue together thin layers of metal powder. Once the part is printed, it’s hardened and placed in a furnace where it’s heated to burn off the binder and fuse the powder into solid metal.

“One of the major findings in the research is that by adjusting the amount of oxygen in the atmosphere during the debinding process, we can effectively remove the binder and reduce oxidation of the powder, while still maintaining the strength of the brown parts,” says Kai Zissel.

Why the right atmosphere matters

Kai Zissel’s research explores how different gas compositions during curing, debinding, and sintering affect final part quality, material purity, and the ability to recycle the powder.

“The importance of the processing atmosphere during these steps is often overlooked. However, we can show that by using specific gas mixes we can improve the entire process from printing to heat treatment, resulting in much better part quality,” says Kai Zissel.

For example, curing in air can cause powder oxidation, making it difficult to reuse the powder. Using inert atmospheres during curing prevents this. Another example is the debinding process, where inert atmospheres leave binder residues that affect the final part quality. Reactive gases like hydrogen are better for removing the binder, but hydrogen comes with safety concerns.

“By combining a reduced oxygen content in the debinding atmosphere with sintering using inert gases like argon, we can achieve material properties close to those processed with hydrogen. If we combine the debinding in a tailored gas mix with sintering in hydrogen, we can even further improve the material properties,” says Kai Zissel.

By using specific gas mixes we can improve the entire process from printing to heat treatment, resulting in much better part quality.

From research to application

Pierre Forêt, Global Associate Director of Additive Manufacturing at Linde, and industrial supervisor for Kai Zissel, emphasizes the practical impact of this research.

“Kai’s research has given us valuable insights into a very young technology. Thanks to this research, we are now at a level where we have a gas product that can help end users improve their binder jetting process,” says Pierre Forêt.

While binder jetting is still developing as a technology, interest from industry is growing steadily.

“We’ve developed the right solution, and with adoption expected to grow in the coming years, the full impact of this research will become increasingly clear as the technology matures,” he says.

Bridging academia and industry

Kai Zissel pursued his PhD in an industrial setting within the framework of the CAM2 centre at Chalmers, to combine the strengths of both academia and industry.

“I wanted to work on something with direct industry impact while still being immersed in a highly scientific environment. It’s been a fantastic opportunity to experience both worlds, seeing the challenges and strengths of each,” says Kai Zissel.

Pierre Forêt highlights the strategic importance of such collaborations.

“At Linde, we’ve always valued strong partnerships between industry and academia. When we started exploring binder jetting, collaborating with Chalmers and CAM² was a natural choice. Their expertise in powder metallurgy and binder jetting aligned well with our objectives in advancing metallurgy,” he says.

What’s next?

As for the future, Kai Zissel sees himself continuing to work at the intersection of research and industry.

"I enjoy working on research that has real-world applications, seeing it eventually take off and be used. While I value the depth of academic research, I want to help turn innovations into practical use, ideally in a role that connects both academia and industry," he says.

Read more

Interested in diving deeper into the research? Here are two scientific papers by Kai Zissel.

Impact of oxygen content on debinding of binder jetted 17-4 PH stainless steel: Part I – Debinding

Impact of oxygen content on debinding of binder jetted 17-4 PH stainless steel: Part II – Sintering

Kai Zissel defends his PhD thesis on 26 May

Read the thesis and see the time and location of the defense.