The division integrates computational mechanics and advanced materials technology. It combines multidisciplinary expertise to predict, understand, and elevate the performance of engineering materials and structures. A broad range of research areas, methods, and applications is included.

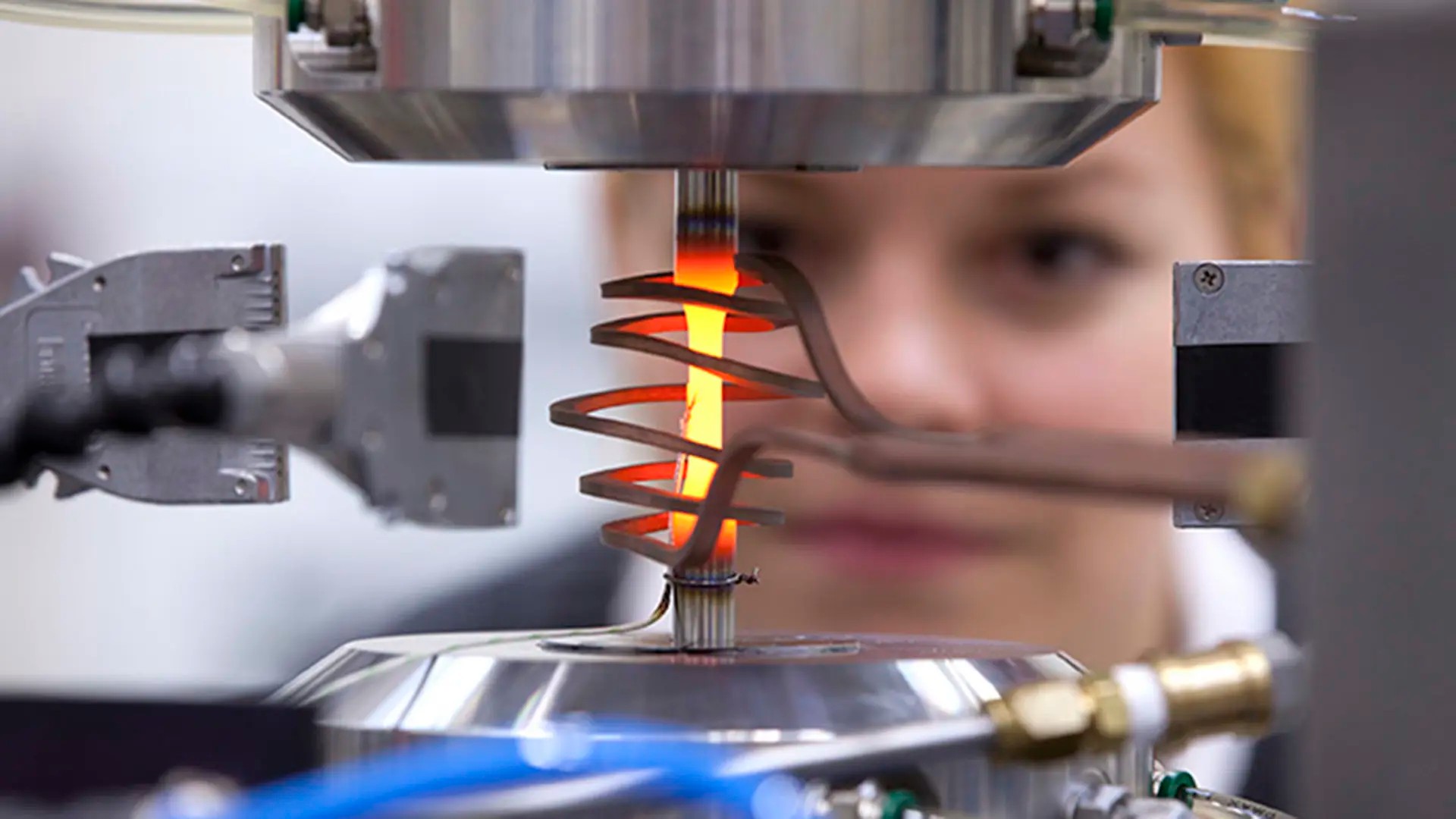

The bulk of the research focuses on the relationship between the microstructure of technological materials and their mechanical properties. The mechanical modeling addresses prediction of material failure, energy absorption, and fatigue properties in metals, polymers, and composites. The experimental methods employed are different forms of mechanical testing, various types of microscopies, image analysis, fractography, etc. Key applications are railway mechanics and mega-casting of aluminum. The aim is to reduce life-cycle costs and reduce the environmental footprint.

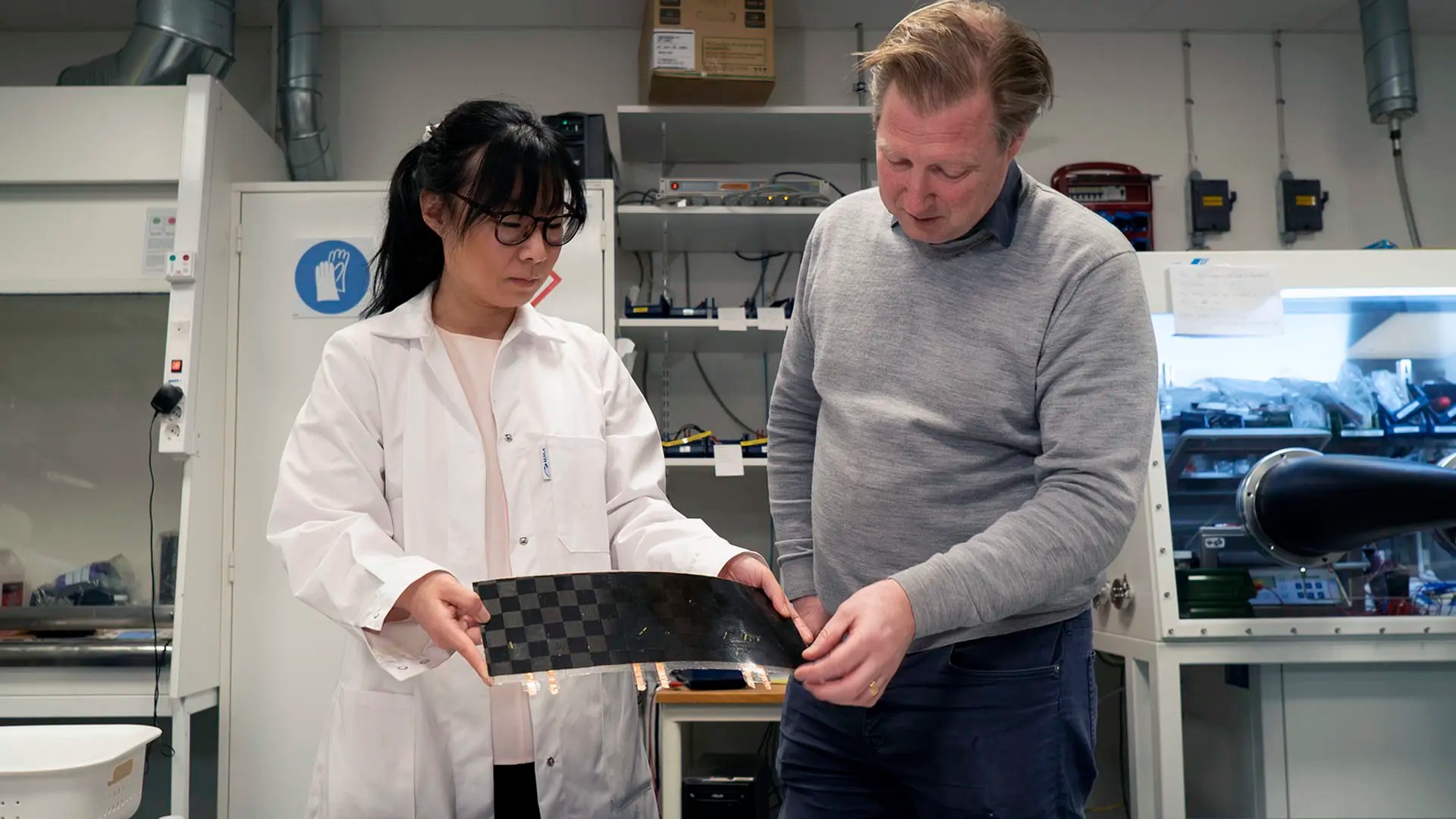

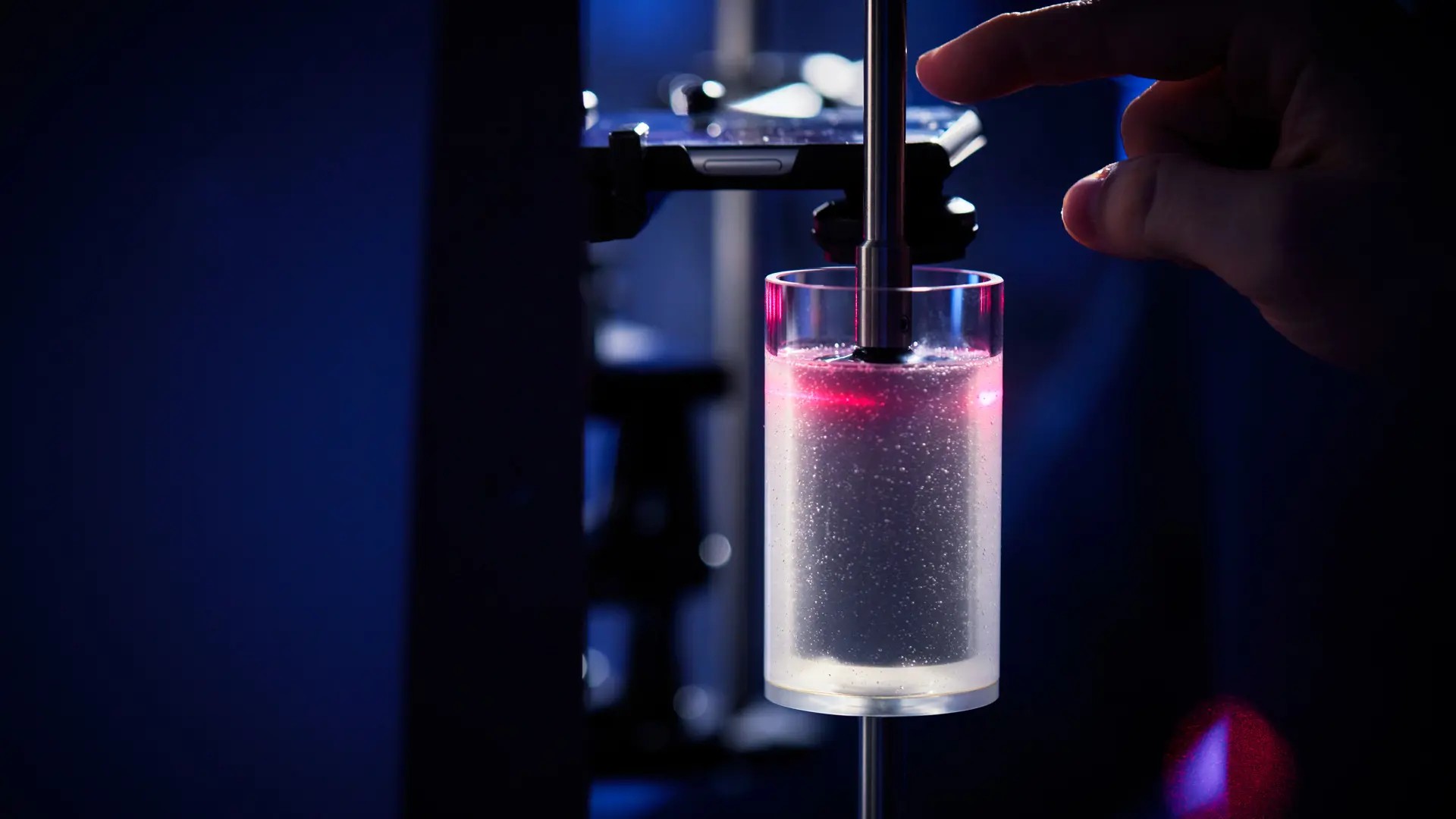

A significant portion of the research concerns the development of multifunctional materials. By bridging the interface between electrochemistry and computational mechanics, we contribute to the next generation of structural batteries, which are polymer composites that simultaneously store energy and carry mechanical load. New or improved functional properties are also developed for nanocomposites with the corresponding manufacturing techniques. It also includes developing sustainable solar energy materials using accelerated experimental technology.

Through this integrated approach and our strong commitment to teaching and research, we strive to deliver sustainable mechanics-based technology solutions that meet the evolving needs of modern engineering and sustainability.

Active areas

Head of Division

- Head of Division, Material and Computational Mechanics, Industrial and Materials Science