Collaboration between humans and robots, self-learning systems, and an increased focus on sustainable and flexible production. The field of automation has evolved from a specialized technical field to a key part of today’s technological transformation, something Bengt Lennartson, Professor of Automation at Chalmers University of Technology, has followed closely.

"Getting robots and humans to work well together, that’s one of the truly big challenges right now," Bengt Lennartson says.

A constantly evolving field

When Bengt Lennartson founded the automation research group at Chalmers in 1999, the field was still young within academia. Its roots are in control theory, the science of responding to changes in technical systems based on feedback control. Since then, automation has expanded from controlling individual machines to managing entire production flows, now combining methods from control engineering, computer science, and artificial intelligence.

“The development of computer technology and what we now call Internet of Things has been key. We’ve learned to refine methods from computer science and apply them to production environments.”

But the applications of automation are not limited to industry. In healthcare, similar methods are being used to optimize scheduling and resource allocation, areas where smart planning can make a significant impact.

“Scheduling is essentially an optimization problem. In fact, it is one of the biggest in the world. It’s used to create efficient flows in industry, but it can also help make better use of resources in healthcare.”

Robotics are changing the game

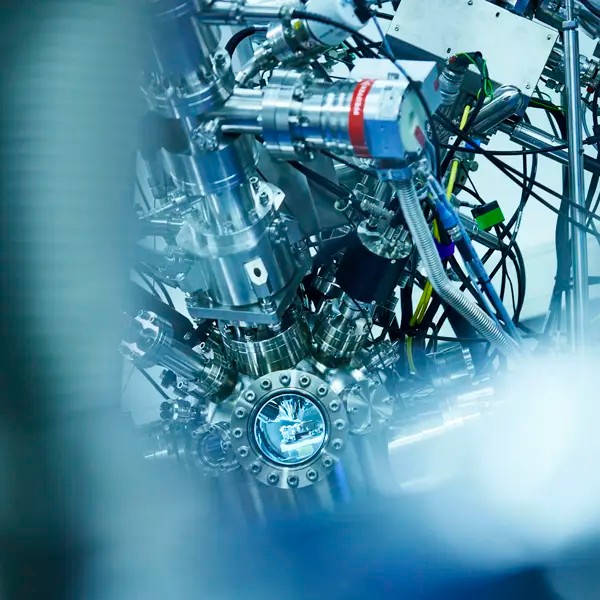

Robotics has long been a strong driver of automation. One example is a collaboration with Volvo Trucks, where automated guided vehicles (AGVs) combined with advanced vision systems are helping to redefine production organizations. Overhead cameras provide a full view of the factory floor, offering an entirely new perspective on automation in production facilities.

“This is proof of the impact of our work, that automation truly makes a difference. It holds enormous potential for the future.”

Today, automation is not just about replacing manual tasks but about creating effective interaction between humans and machines, where robotic precision and endurance complement human flexibility.

“Robots can relieve us of repetitive or physically demanding tasks. It’s not about replacing people but about using all resources in the best possible way.”

Wingquist Laboratory – a platform for collaboration

Wingquist Laboratory has been a key platform for automation research at Chalmers. Here, the automation group works across disciplines with the center’s three other research groups to tackle shared challenges.

“The strength lies in being a large constellation with different perspectives. It has led to strong collaborations internally and has been crucial for building networks with industry.”

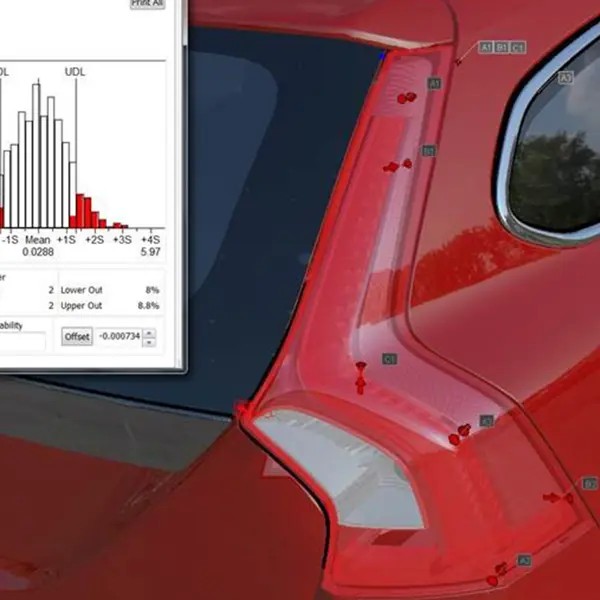

One example of this collaboration is the Smart Assembly 4.0 project, where researchers from multiple disciplines and industry partners developed new methods for self-adjusting and quality-assured assembly. By combining advanced sensor technology and reinforcement learning, the assembly process can be optimized based on each individual component.

“Wingquist Laboratory has long been an important engine for collaboration. We’ve inspired one another to explore new research questions, which has led to projects that truly drive development forward.”

The future of automation demands new skills

Looking ahead, Bengt Lennartson highlights AI and optimization as key areas for the future of automation. The pace of development is high, and it’s important to harness it in the right way to meet future needs.

“In-depth knowledge in AI, optimization, and systems engineering will be crucial. We need to stay at the forefront to develop solutions independently.”

He also emphasizes the importance of understanding dynamic systems, systems that don’t respond instantly but require the ability to predict and adjust for delays.

“Optimization is a key tool in almost every technical field. When combined with an understanding of how dynamic systems behave, we can develop solutions that actually work in practice.”

Research groups at Wingquist Laboratory

Learn more about the four research groups in the centre.

- Full Professor, Systems and Control, Electrical Engineering