“Digital Product Realization” is the key to efficient and sustainable product and production development. Extensive research in this area is therefore crucial for the competitiveness of the Swedish manufacturing industry. It opens possibilities for new research and innovations like no other disruptive trend today.

Taking on the challenges related to the broader area of digitalization includes research challenges such as:

- How to utilize extended amounts of data

- How to increase efficiency and accuracy in modeling, simulation and optimization of complex systems

- How to include more intelligence in products and production systems

- How to increase connectivity between systems

- How to allow for increased individualization in products and processes

Research within the centre is essentially case-driven and cross-disciplinary with focus on the industrial process. Focusing on processes is a very efficient way to conduct applied research since real industrial needs are identified and solved at the same time as the need for new and sometimes deeper research is identified. The research procedure allows for both high-level, cross-disciplinary research as well as deep, intra-disciplinary research.

Research projects are initiated by new scientific approaches with the potential to drastically change the way the collaborating companies do business in the future. One important factor needed to succeed with this is the possibility to demonstrate the industrial potential of different approaches by using implementation cases. All the collaborating industrial partners approve of the centre’s use of real product data for analyses and tests.

Focus

Digital product and production development is a crucial enabler for future industrial competitiveness, growth and sustainable production. The ability to develop and verify complex assembled products and their production systems, without physical prototypes or testing, cuts development time and cost and contributes to reduced resource use. It also contributes to better working conditions.

Research Groups

Four complementary research groups at Chalmers and Fraunhofer-Chalmers Centre are gathered in the centre. In total there are 50 researchers (5 professors, 20 senior researchers and 25 PhD students) and approximately 70 engineers from industry who are working together on the vision of virtual product realization. From an international point of view, it is unusual to have such a large group of people sharing the same vision and focus.

Research projects and publications

In Chalmers research database, Research, you can find our researchers' publications and research projects.

Strategies & key issues

Research strategy

Within Wingquist Laboratory product development and production system development are treated together. Effective and efficient production at high quality requires a product that is well adopted to the limitations of the present production system and vice versa, and robust to its inherent variation. Strategies for how product families are built up based on platforms and modules with common and unique components, equipment and knowledge are controlled by the product architecture.

Requirements on the final product are broken down to requirements on subsystems, components, fixtures, assembly sequence, welding sequence etc. This also controls the way the flow in the factory is designed and the balance between individual production cells. The interfaces between components and systems are critical for the ability to modularize, configure and create product variants.

Simulation and visualization are powerful techniques which make it possible to consider both product and productions system aspects simultaneously and to reduce development time. These techniques provide ability for fast testing of a large number of different solutions or scenarios in order to find the one that best balances the requirements. Efficient reuse of knowledge also requires effective and efficient IT systems that can handle all requirement and functionality decomposition from specification to final product.

Implementation strategy

Within Wingquist Laboratory, a routine has been developed over time to drive implementation of results a step further and thereby also secure knowledge transfer in an integrated way. In addition to traditional collaboration with PhD students and master thesis works, Wingquist Laboratory has built up a network of resources that can assist (and benefit from) the knowledge transfer process.

Software for demonstration and use

In the centre, two commercial software packages are being used and developed. These software packages are also used by some of the industrial partners and serve as a very efficient way for fast implementation of research results.

RD&T

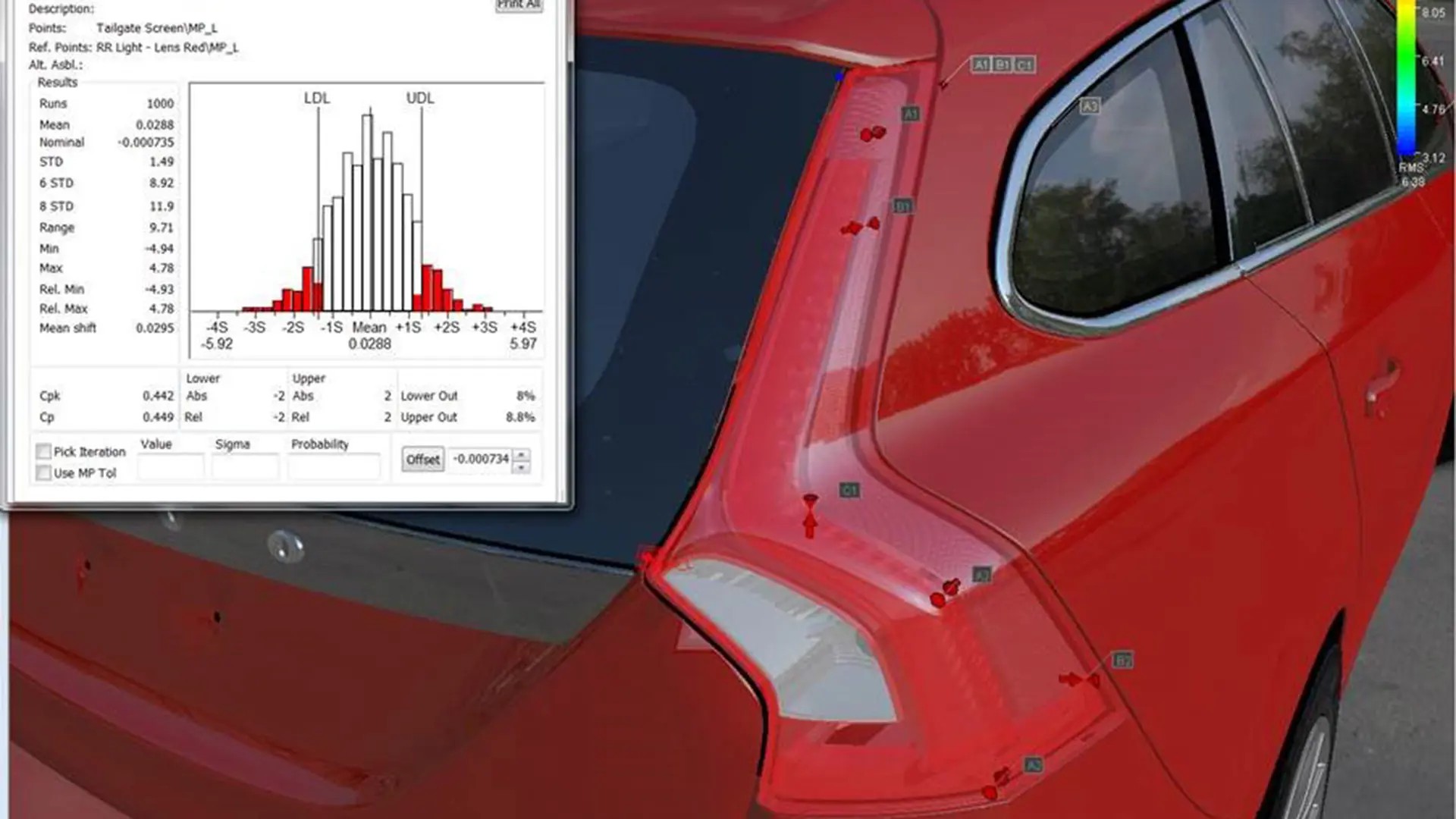

RD&T, from the spin-off company RD&T Technology AB, is a tool for statistical variation simulation that allows manufacturing and assembly variations to be simulated and visualized long before any physical prototypes are being made. RD&T supports the geometry assurance process in all its phases and is mainly developed by the Geometry Assurance & Robust Design research group.

IPS

IPS, from the spin-off company IPS Sweden AB, is a math based tool for automatic verification of assembly feasibility, design of flexible components, motion planning and optimization of multi-robot stations and simulation of key surface treatment processes. IPS is mainly developed by the Geometry & Motion Planning research group.

Utilized by industrial partners

The software packages RD&T and IPS are used by Volvo Car Group, Volvo Group Trucks Technology, GKN Aerospace Engine Systems and Scania CV.