The combined emissions of metals and other environmentally hazardous substances from ships is putting the marine environment at risk according to a new study from Chalmers University of Technology, Sweden. When the researchers calculated the contaminant load from these emissions into the marine environment in four ports, it was found that water discharged from ships’ scrubbers, whose purpose is to clean their exhaust gases, accounts for more than 90 per cent of the contaminants.

“The results speak for themselves. Stricter regulation of discharge water from scrubbers is crucial to reduce the deterioration of the marine environment,” says Anna Lunde Hermansson, a doctoral student at the Department of Mechanics and Maritime Sciences at Chalmers.

Traditionally, environmental risk assessments (ERA) of emissions from shipping are based on one source at a time. For example, the ERA might look at the risk from copper in antifouling paints. But as with all industries, shipping is an activity where there are multiple sources of emissions.

“A single ship is responsible for many different types of emissions. These include greywater and blackwater, meaning discharges from showers, toilets and drains, antifouling paint, and scrubber discharge water. That is why it’s important to look at the cumulative environmental risk in ports,” says Anna Lunde Hermansson who, with colleagues Ida-Maja Hassellöv and Erik Ytreberg, is behind the new study that looked at emissions from shipping from a cumulative perspective.

A scrubber can be described as a cleaning system for the exhaust gases arising from the combustion of heavy fuel oil, which has been the most common fuel used in ships since the 1970s. Seawater is pumped up and sprayed over the exhaust gases to prevent emissions of airborne sulphur reaching the air.

Scrubbers mean that ships can comply with the requirements introduced by the International Maritime Organization (IMO) in 2020. The only problem is that the water not only takes up the sulphur from the exhaust gases, leading to acidification of the scrubber water, but also other contaminants such as heavy metals and toxic organic compounds. The contaminated scrubber water is then often pumped directly into the sea.

Hundreds of cubic metres of contaminated water every hour

“There is no cleaning step in between – so up to several hundred cubic metres of heavily contaminated water can be pumped out every hour from a single ship. Although new guidelines for ERAs of scrubber discharges are in progress, the ERAs still only assess one source of emissions at a time, which means that the overall assessment of the environmental risk is inadequate,” says Lunde Hermansson.

In this new study, the researchers at Chalmers looked at four different types of port environments to determine contaminant concentrations from five different sources. Actual data from Copenhagen and Gdynia were used for two of the ports. They were selected due to high volumes of shipping traffic, and a substantial proportion of these ships having scrubbers.

The results showed that the cumulative risk levels in the ports were, respectively, five and thirteen times higher than the limit that defines acceptable risk.

Port descriptions used internationally in ERAs were utilised for the other two port environments. One of these environments has characteristics typical of a Baltic Sea port, while the other represents a European port with efficient water exchange due to a large tidal range.

The researchers found that three out of the four port environments were prone to unacceptable risks according to the assessment model used. They also saw that it was emissions from antifouling paint and scrubber discharge water that accounted for the highest levels of hazardous substances in the marine environment and had the highest contribution to the risk. More than 90 per cent of the environmentally hazardous metals and PAHs (polycyclic aromatic hydrocarbons) came from scrubber discharge water, while antifouling paints accounted for the biggest load of copper and zinc.

Total load is what causes the damage

“If you look at only one emissions source, the risk level for environmental damage may be low or acceptable. But if you combine multiple individual emissions sources, you get an unacceptable risk. The marine organisms that are exposed to contaminants and toxins don’t care about where the contaminants come from, it is the total load that causes the damage,” says Lunde Hermansson.

The only port environment that showed an acceptable risk in the researchers’ ERA was the model with the highest water exchange per tidal period, meaning that a high volume of water is exchanged in the port as the tide moves in and out.

“It’s important to remember that the contaminated water doesn’t just disappear – it is transported elsewhere. In the port environments studied, there might be a kind of acceptance of environmental damage – that in this particular environment we have decided that we will have an industry and that it will result in pollution. However, when the contaminated water is washed out to sea, it can end up in pristine sea areas and have even greater consequences. This is something we address in our research. We look at the total load, how much is actually discharged into the environment,” says Lunde Hermansson.

Having scrubbers on a ship is not a requirement. They are installed and used as an alternative to switching to a cleaner and more expensive fuels that emit lower volumes of metals and PAHs. Scrubbers allow ships to continue using the much cheaper and more polluting heavy fuel oil. Heavy fuel oil is a residual product in the distillation of crude oil, and is now used only in maritime transport.

Economical to install scrubbers

Since the mid-2010s, the number of ships with scrubbers installed has increased. In a study conducted in 2018, it was found that there were 178 ships with scrubbers operating in the Baltic Sea. Today, the researchers estimate that there is triple that number. Globally, there are about 5,000 such ships, representing around five per cent of the total fleet.

“But it’s the large ships with high fuel consumption that install scrubbers, because it is more economical for them to do so. So we anticipate that they would account for somewhere around 30 per cent of total fuel consumption in shipping,” says Lunde Hermansson.

She points out that the use of heavy fuel oil as a ship fuel also contradicts the commitments that the IMO has said it wants to make, such as reducing greenhouse gas emissions from shipping by 50 per cent by 2050. The Swedish Agency for Marine and Water Management and the Swedish Transport Agency have submitted a proposal to the Swedish Government to prohibit the discharge of scrubber water into internal waters, that is, waters that lie within the Swedish archipelago.

“It’s a step in the right direction, but we would have liked to see a stronger ban that extends across larger marine areas, while we also understand the challenge for individual countries to regulate international shipping,” says Erik Ytreberg, an associate professor at the Department of Mechanics and Maritime Sciences at Chalmers.

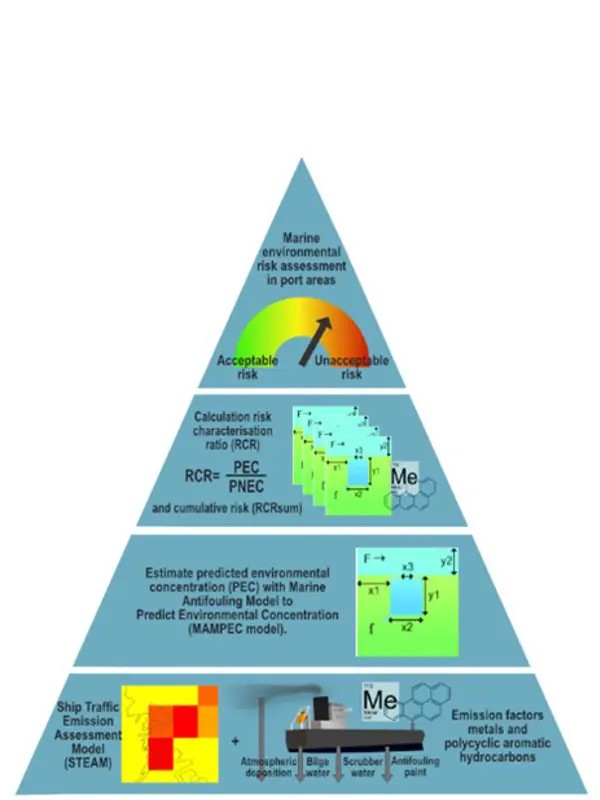

How the risk assessment in the four ports was carried out

The work to assess the environmental risk in the ports was carried out following a bottom-up approach (see the illustration).

In Step 1 (at the bottom), the loads from various emission sources from shipping were calculated. The volumes were estimated using STEAM, a model that assesses emissions from ship traffic. The volumes were combined with specific concentrations of the substances within each emissions source to calculate the load of the different substances.

In Step 2, the daily load was used to estimate the resulting concentrations in the environment, called PEC or predicted environmental concentration, using the MAMPEC model. The model calculates PEC for a defined environment (in this case a port), using the properties of the substances (in this case of 9 metals and 16 polycyclic hydrocarbons) and the daily load of the substances (from Step 1). MAMPEC calculates PEC for one substance at a time at a constant load.

In Step 3, the results were then combined to enable the inclusion of more substances as well as loads from different emissions sources simultaneously. To calculate the environmental risk, the PEC is compared with the limit values that represent the concentration that can be considered safe, in other words, where no negative effect on the marine environment is found. This is also known as the PNEC (Predicted No Effect Concentration). If the PEC is higher than the PNEC, it is said that there is an unacceptable risk.

In Step 4, the risk characterisation ratios (RCRs) from multiple substances were added together, which means you can calculate the cumulative risk and present a more comprehensive environmental risk assessment within an area.

Illustration: Chalmers | Anna Lunde Hermansson

More about the research

The article Cumulative environmental risk assessment of metals and polycyclic aromatic hydrocarbons from ship activities in ports has been published in the journal Marine Pollution Bulletin. The authors are Anna Lunde Hermansson, Ida-Maja Hassellöv and Erik Ytreberg – all working at the Department of Mechanics and Maritime Sciences at Chalmers – and Jukka-Pekka Jalkanen of the Finnish Meteorological Institute. The research was partly funded by the EU project EMERGE within the framework of the Horizon 2020 funding programme.

For more information, please contact:

Anna Lunde Hermansson, Doctoral student, Department of Mechanics and Maritime Sciences, Chalmers University of Technology, Sweden, anna.lunde.hermansson@chalmers.se, +46 31 772 18 66

Erik Ytreberg, Associate Professor, Department of Mechanics and Maritime Sciences at Chalmers University of Technology, Sweden, erik.ytreberg@chalmers.se, +46 31 772 27 49

Ida-Maja Hassellöv, Professor, Department of Mechanics and Maritime Sciences at Chalmers University of Technology, Sweden, ida-maja@chalmers.se, +46 31 772 31 39

- Doctor, Transport, Energy and Environment, Mechanics and Maritime Sciences

- Senior Researcher, Transport, Energy and Environment, Mechanics and Maritime Sciences

- Full Professor, Transport, Energy and Environment, Mechanics and Maritime Sciences