In the competence centre CAM², universities, research institutes, companies and public actors conduct research in close cooperation within the area of additive manufacturing of metal. The centre offers the most complete state-of-the-art infrastructure in Sweden.

The consortium gathers industrial know-how in:

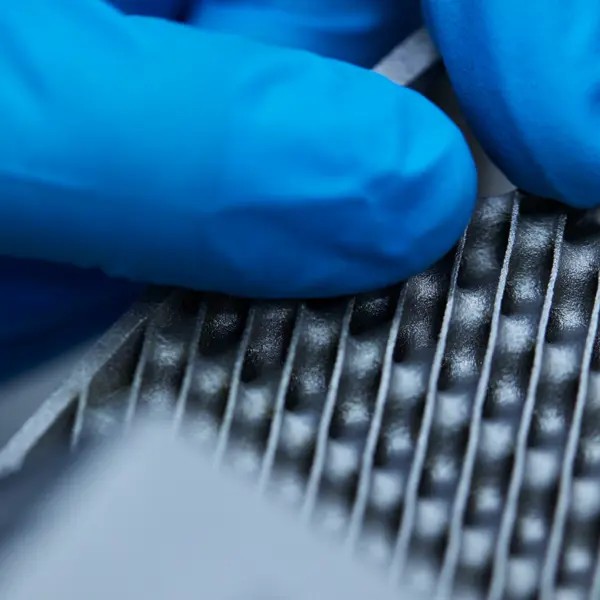

- Powder development

- Hardware: Powder Bed Fusion – Laser Beam (PBF-LB), Powder Bed Fusion – Electron Beam (PBF-EB), Binder Jetting (BJT) and powder-based Directed Energy Deposition (DED)

- High-end manufacturing by additive manufacturing

- Post-processing

Research partners

CAM2 is a collaboration between five research partners. Three universities and two research institutes.

- Chalmers, Department of Industrial and Materials Science - Coordinator

- Fraunhofer-Chalmers Centre

- Linköping University, Department of Management and Engineering

- RISE Research Institutes of Sweden

- University West, Production Technology West group

Industrial partners

CAM2 has today close to 30 industrial partners involved in the centre. They are engaged on three levels.

Core members

- Alfa Laval Technologies AB

- Colibrium Additive

- EOS Finland Oy

- GKN Aerospace Sweden AB

- Höganäs AB

- Saab AB

- Sandvik AB

- Scania AB

- Siemens Energy AB

- SSAB

- Volvo Cars Corporation AB

- Volvo Lastvagnar AB

Basic members

- AddUp S.A.S

- REM Surface Engineering

- RENA Technologies Austria GmbH

- ThermoCalc Software

- Quintus Technologies AB

Small and medium enterprises

- AIM Sweden AB

- Bättre Design Göteborg AB

- Camatec

- Carbex AB

- f3nice

- Goceram AB

- Härdservice AB

- Incus GmbH

- Innomat AB

- InssTek

- Interspectral AB

- Linthoz GmbH

- Permanova Lasersystem AB

- Recotech AB

- Simtec Soft Sweden AB

- VBN Components