Vi bygger upp kunskap och bedriver forskning som tar tillvara kemiteknikens unika möjligheter att skapa nya, renare och smartare lösningar, som kan värna våra resurser, förbättra vår miljö, våra livsvillkor och vår globala hälsa.

Institutionen för kemi och kemiteknik omfattar ett brett fält av grundläggande

och tillämpad forskning. Vi är engagerade i utbildning på grund, doktorand och forskarnivå.

Utbildningar som leder till gott om flexibla, gröna jobb

Arbetsmarknadsprognosen för utbildade civilingenjörer inom kemi och teknik ser mycket bra ut, både nu och i framtiden. Med en utbildning i den här inriktningen finns det också stor chans att du kommer arbeta med något som kan förbättra din omvärld. Ämnesområdet och kompetensen spelar viktiga roller i aktuella framtidsfrågor som till exempel energi, miljö och hälsa.

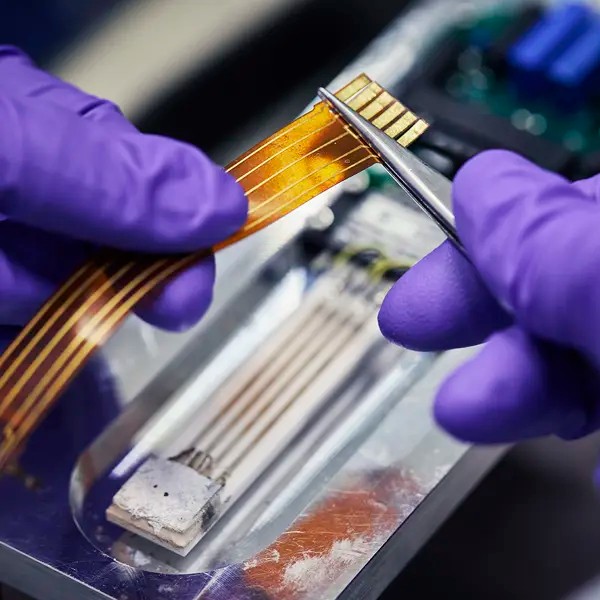

Mångsidig forskning med spetskompetenser

Vår forskning stäcker sig från grundläggande kemi, kemi i gränssnittet till biologi och medicin, materialvetenskap, förnybar energi, till kemitekniska processer, materialåtervinning, kärnkemi, liksom teori och modellering.Vi har projekt och expertis som ligger långt fram inom särskilda fält, och presenterar forskningsresultat som påverkar och väcker stort intresse i omvärlden.

Innovationer och samarbeten med samhällsnytta

Ett viktigt syfte med vårt arbete är att bidra till nya lösningar som kan göra skillnad och nytta i samhället. Vi samarbetar med industri, offentliga aktörer och andra lärosäten. Innovationer och entreprenörer föds regelbundet hos oss.

Aktuella examensarbeten inom kemi och kemteknik

Är du intresserad av att göra ett examensarbete inom kemi och kemiteknik? Läs vår lista över tillgängliga projekt.

Through curiosity and knowledge towards a sustainable world