In the modern chemical industry the aim is to achieve high-quality products and minimise unwanted by-products. Effective chemical engineering design can lead to improved product quality, reduced negative impact on our environment, taking better care of our resources, increased efficiency, and reduced costs for manufacturers.

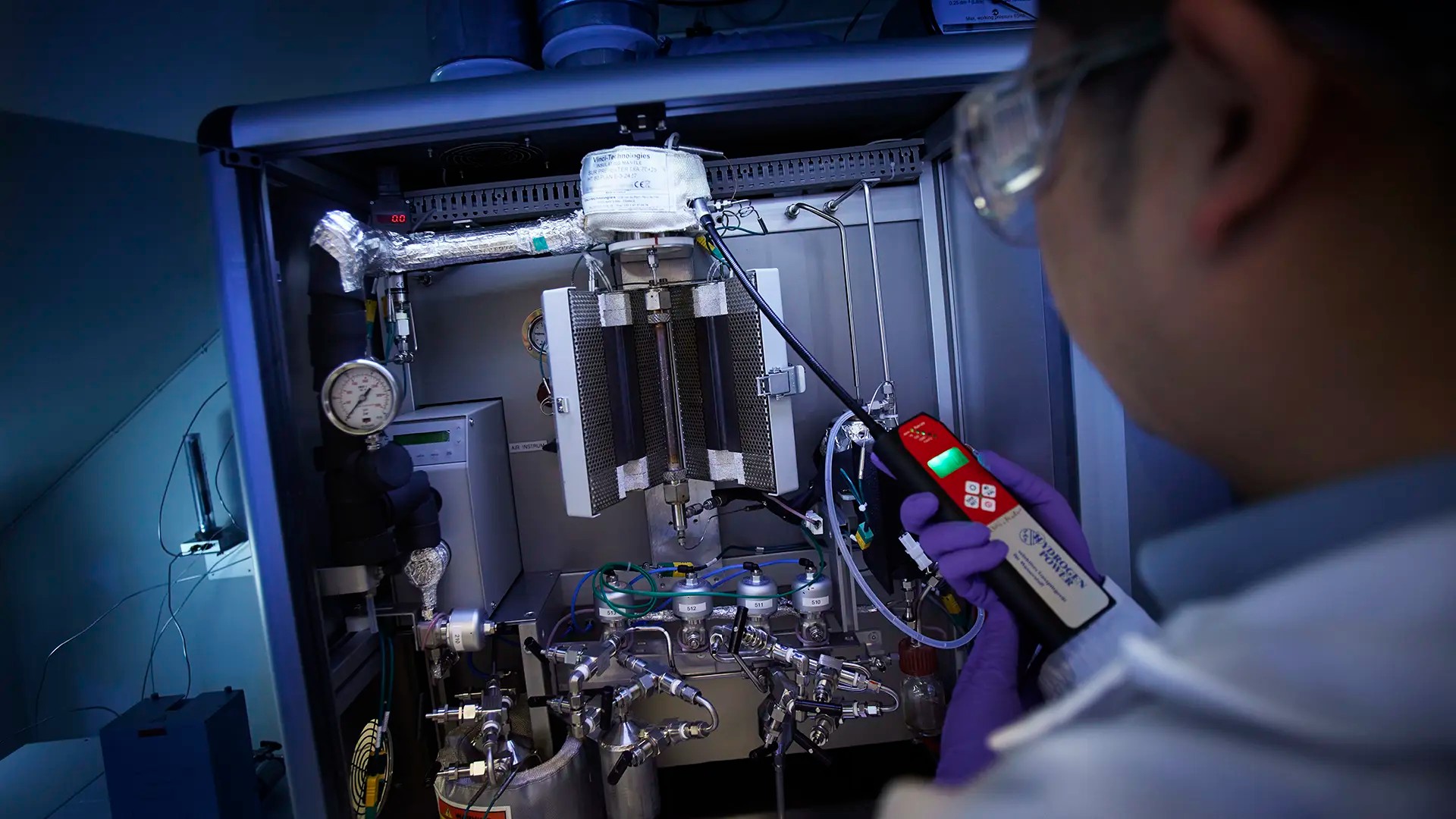

Chemical Reaction Engineering

In the modern chemical industry the aim is to achieve high-quality products and minimise unwanted by-products. Selectivity in the reactor is particularly important in processes in which by-products cause environmental problems (e.g. NOx and CO in exhaust gases from automobiles). In processes where very high purity is required for legislative reasons, such as in the pharmaceutical industry, the cost of purification becomes important and reactor performance is of vital significance. Knowledge of the advantages and drawbacks of chemical reactor properties is therefore essential for all chemical and biochemical processes. Research in chemical reaction engineering includes the kinetics and dynamics of chemical and biochemical processes coupled with molecular mass transport phenomena. Other important research fields are turbulence modelling linked to chemical reaction, fermentation processes, catalyst deactivation, process control, stability and optimisation.

Chemical Engineering Design

Chemical engineering design is the process of designing and optimizing chemical processes and equipment to achieve desired outcomes such as product quality, efficiency, and safety. It involves the application of chemical, physical, and biological principles to develop new chemical products, processes, and technologies. Chemical engineers use their knowledge of chemistry, thermodynamics, and fluid dynamics to design equipment and processes that can produce chemicals, fuels, pharmaceuticals, and many other products. They also consider economic factors, environmental impact, and safety regulations when designing chemical processes. Effective chemical engineering design can lead to improved product quality, reduced negative impact on our environment, taking better care of our resources, increased efficiency, and reduced costs for manufacturers.

The research areas include:

• Transport operations and processes in particulate and porous media (including filtration, dewatering, washing, drying, coating and gas/fibre flow)

• Mixing in two- and three-phase systems (including solids suspension, pulp fibre suspensions, bubble columns, flocculation and liquid/liquid)

• Physico-chemical data for engineering processes