"Receiving funding for scientific equipment on this level is very special and provide a tremendous strength for materials research at Chalmers," says Per Malmberg, one of the researchers who is now receiving funding.

Three platforms at Chalmers will receive SEK 37.5 million when Wallenberg's research initiative WISE invests another half a billion SEK in materials science for increased sustainability - the largest investment of its kind ever in Sweden.

To combat climate change and transition to a sustainable society, there is a great need for new advanced materials.

In January 2024, the Wallenberg Initiative Materials Science for Sustainability (WISE) announced an investment of SEK 500 million in equipment and infrastructure at seven Swedish universities. This involves both basic and applied research to discover and understand new properties in materials.

The investment strengthens three platforms in materials science at Chalmers:

Chemical imaging

Per Malmberg, Associate Professor at the Department of Chemistry and Chemical Engineering, is responsible for the platform.

" "The challenge of replacing fossil materials is enormous. To succeed, we must understand how materials can be built up molecularly with sustainable materials as a basis. We will now complement our infrastructure with a new instrument, a so-called MALDI mass spectrometer. The instrument can refine the technology to understand what kind of molecules you have and how they relate to each other on the surface".

- "There are a lot of different techniques we can use to increase our understanding of the structure of materials. We can do it in two and three dimensions. With the new instrument, we can more easily see molecules and how they are distributed on the surface of a particular material," says Per Malmberg, emphasising that the instrument is part of Chalmers' infrastructure for chemical imaging and is open to all researchers.

"Today we have good instrumentation, but the new addition gives us expanded opportunities when, for example, studying and developing bioplastics built from renewable basic molecules instead of fossil fuels, or organic electronics built from carbon-based molecules as an alternative to silicon. This could lead to cheaper, lighter and more environmentally friendly solar cells, TV screens, LEDs and in-body biosensors".

NAP-XPS for sustainable materials

This platform will establish a node within WISE's newly established Near Ambient Pessure X-ray Photoelectron Spectroscopy (NAP-XPS) platform, led by Julia Maibach, Assistant Professor at the Department of Physics.

“Together with Linköping and Uppsala Universities, we will build a coordinated platform for in-house NAP-XPS with three instruments optimized for different types of sustainable materials. Today the technology is available at MAX IV. Our goal is to increase the general use of NAP-XPS by bringing the technology to university laboratories and developing new methods to study interfacial processes. Therefore, we will provide user support and training activities within the platform that is accessible to the broad Swedish research community in academia and industry", says Julia Maibach.

"At Chalmers, we will focus on increasing our fundamental understanding of electrochemical interfacial processes. It is these processes that determine how efficiently a battery or an electrocatalyst can work, but they are also relevant for corrosion. NAP-XPS allows us to work with complex, real-world devices, but also to use simplified model systems for key interfaces in more realistic environments. Both types of experiments are important for developing safe, stable and sustainable energy storage and conversion solutions for the future".

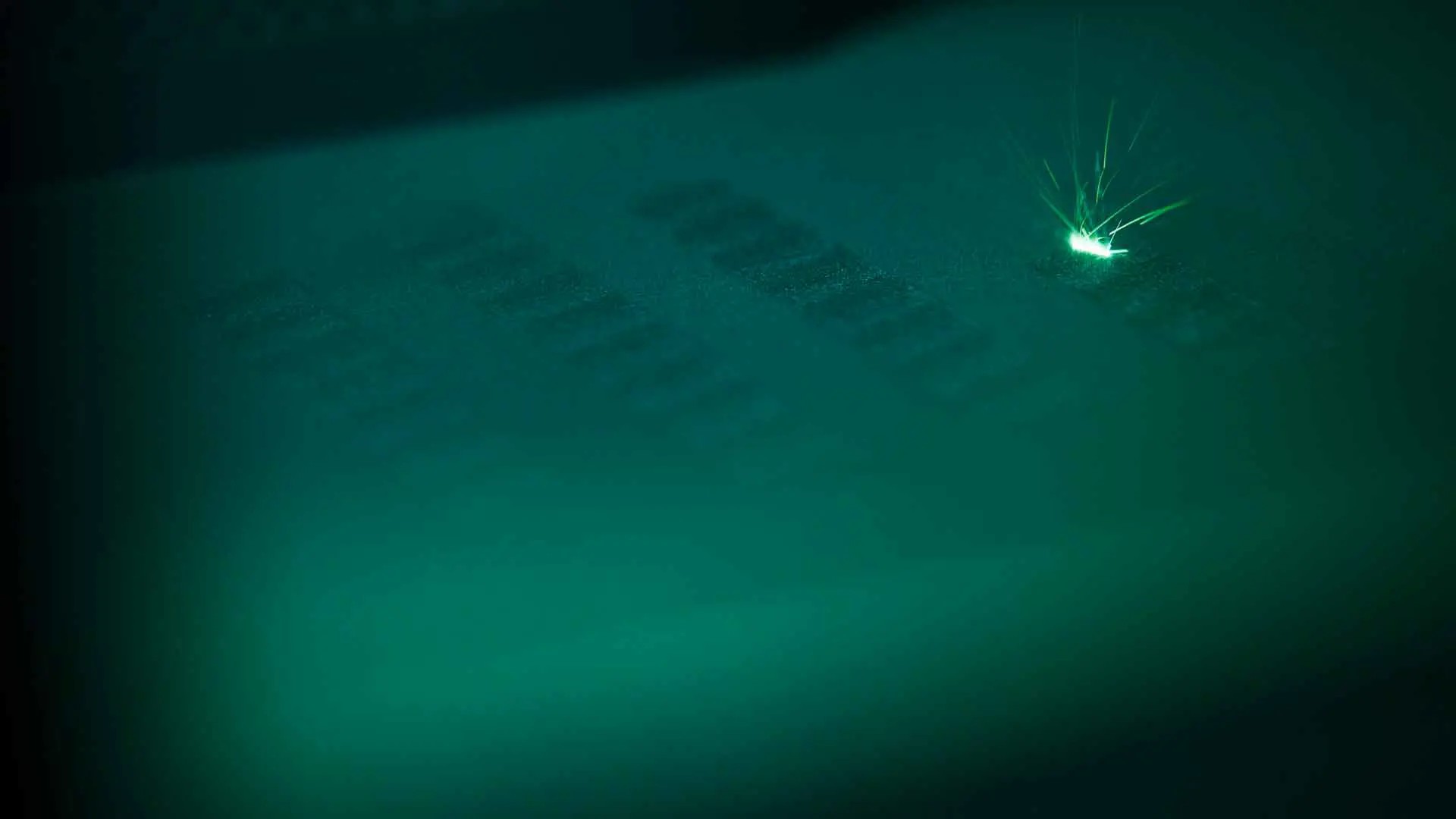

Additive manufacturing

The third platform focuses on the research area of additive manufacturing (AM). The aim is to accelerate the development and industrial implementation of sustainable multi-material additive manufacturing.

Responsible is Eduard Hryha, Professor at the Department of Industrial and Materials Science:

Such a unique infrastructure will make it possible to manufacture complex multi-material components such as gradient magnetic materials, printing batteries, multifunctional components for structural and energy technology applications, etc.

“Multi-material AM is a rather unexploited area with great potential for the development of a new generation of materials for a variety of multifunctional components. When it comes to the sinter-based metal AM, where the hosting group at Chalmers has a heritage of more than 70 years, the addition of infrastructure to enable multi-material metal/ceramic AM will allow to boost development and industrial utilization of novel multifunctional materials. Such an infrastructure is not currently available in Scandinavia. This also contributes to the development and industrial utilisation of new multifunctional materials and processes”.

"The initiative strengthens the position of Swedish academia and industry in research and development of new materials using state-of-the-art additive manufacturing technologies," says Eduard Hryha, citing as an examples material for sustainable multifunctional components linked to energy efficiency and energy storage.

Eduard Hryha says it is crucial that our future engineers and researchers have access to cutting-edge infrastructure and expertise in future materials and technologies enabled by additive manufacturing:

"It provides a breeding ground for AM materials and technology development, research, education and effective industrial implementation so that Sweden can strengthen its position as one of the leading countries in sustainable material and technology development”.

FACTS:

WISE is a collaboration between the leading universities in Sweden in the field of materials science: Linköping University, Uppsala University, Chalmers University of Technology, Royal Institute of Technology, Stockholm University, and Luleå University of Technology. WISE wants to increase competence in the entire Swedish infrastructure. The instruments are open to all researchers in Sweden within the WISE major initiative.

Together with industry and society, the initiative will promote and accelerate the transition to a sustainable society. It will also advance the scientific frontier in materials science, strongly establishing Sweden as a leading nation in the field.

In the left column you will find contact information for some of the key researchers for WISE at Chalmers.

More about the WISE platforms in Sweden

Infrastructures for transmission- and scanning electron microscopy, photoelectron spectroscopy, nuclear magnetic resonance and magnetic resonance imaging, mass spectroscopy, crystallography, additive manufacturing, as well as dedicated fabrication and synthesis laboratories for electronic and circular materials are being financed. Several of the research technology platforms will be organized as distributed infrastructures, with complementing equipment hosted at individual universities. Substantial additional financing and support are also provided by the WISE partner universities.

The equipment is expected to be commissioned in 2024 and run throughout the entire WISE project period. For the more time-consuming build-up of certain WISE research platforms, the equipment is expected to be in operation during 2025.

Related:

Technology platforms - WISEWISE (wise-materials.org)

Wallenberg Initiative Materials Science for Sustainability, WISE

- Associate Professor, Chemistry and Biochemistry, Chemistry and Chemical Engineering

- Assistant Professor, Materials Physics, Physics

- Full Professor, Materials and Manufacture, Industrial and Materials Science