Chalmers' research is here presented through a number of research areas that bring together expertise from several departments, and with a focus on global societal challenges. For other research at Chalmers, please visit the departments' pages.

Energy

For a transition to sustainable energy systems and a common understanding of long-term challenges.

Health Engineering

Sustainable solutions to major health-related societal challenges, in close collaboration with the healthcare sector.

ICT, digitalisation and AI

Aiming for a smarter, safer society.

Materials science

We enable the green transition through excellent materials science in energy, health, construction and transport.

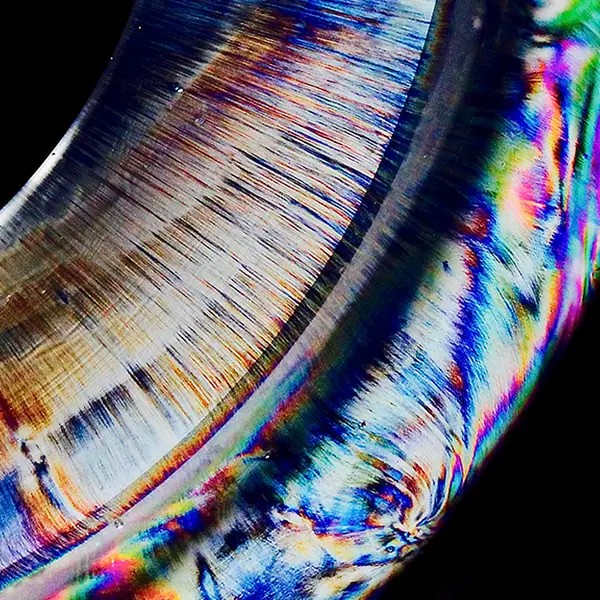

Nano and Quantum Science and Technology

Research into the unique physical, chemical and biological phenomena that prevail at very small dimensions, and the technologies that utilise these phenomena.

Ocean

Research, education, and or utilisation related to the marine and maritime domain, contributing to the grand challenges associated with human utilisation of the oceans and marine resources.

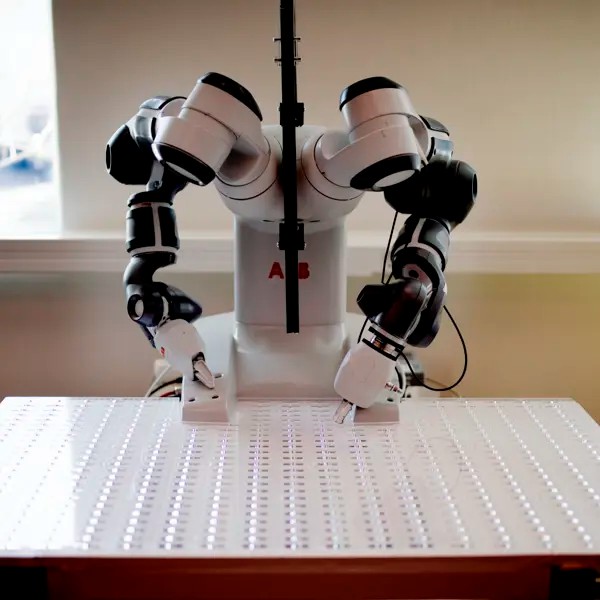

Production

Sustainable industry through the transition to a circular economy, industrial digitisation and the use of new materials.

Space

A sustainable approach to space technology meeting societal and scientific challenges now and in the future, on Earth and beyond.

Transport

New knowledge to meet transport-related challenges in accordance with global goals for safe, sustainable development.

13 Departments

You will find more research at our departments.